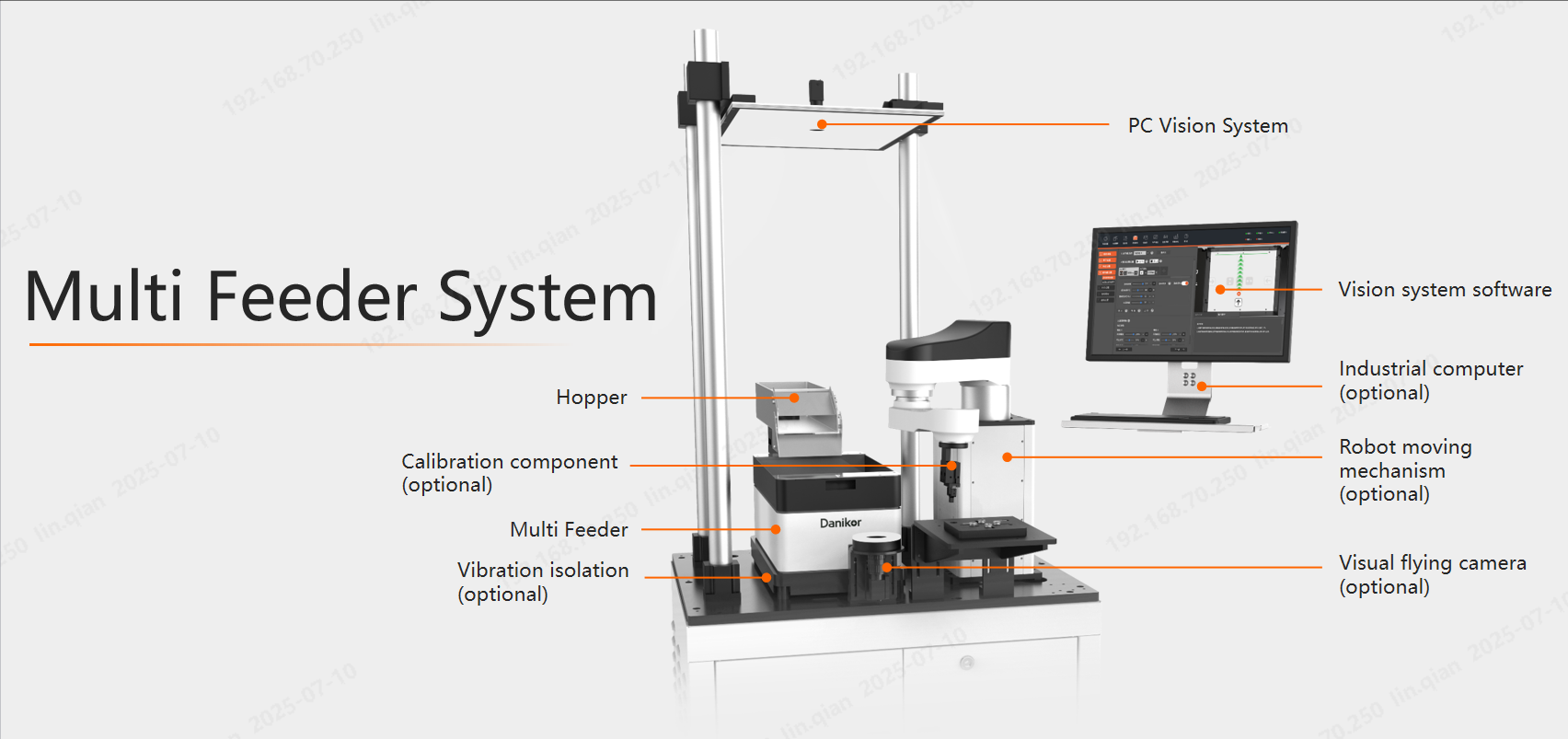

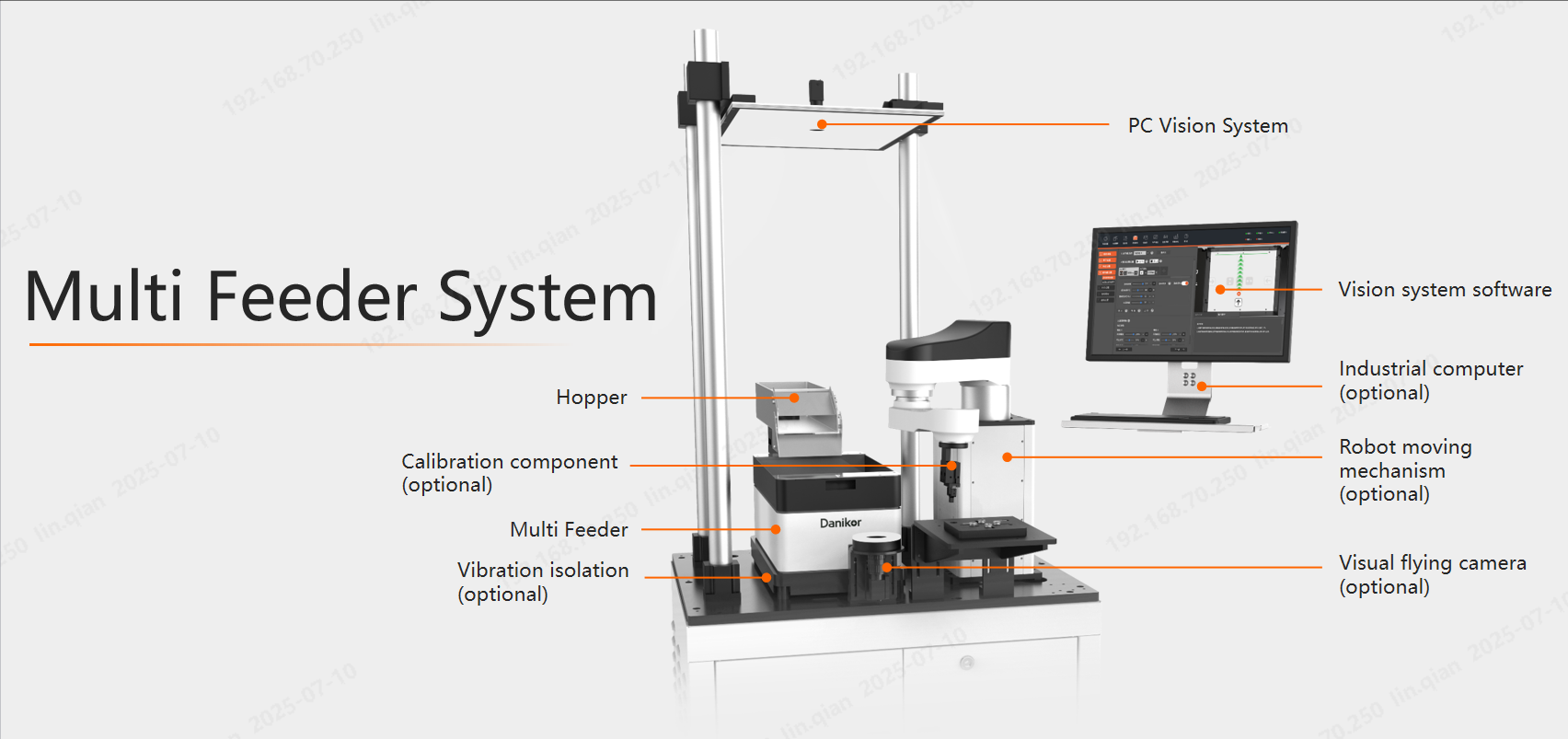

Danikor Flexible Feeder: Solving Multi-Variety Mixed-Line Production Feeding Challenges

In today's manufacturing industry, multi-variety, small-batch production modes are becoming increasingly common, placing higher demands on production line feeding systems. Traditional vibratory feeders often have limitations when handling materials of different specifications and materials, such as poor tray compatibility, cumbersome changeover, and difficulty adapting to compact workstations. The emergence of Danikor's flexible vibratory feeder provides an effective solution to these challenges.

Danikor's flexible feeder features a highly compatible tray design that can adapt to materials of various materials and sizes. Whether they are metals, plastics, or electronic components, materials of different sizes and shapes can be arranged and conveyed in an orderly manner on the tray. Moreover, based on the special properties of the materials, such as easy rolling or static electricity, the tray can be customized with designs such as holes, slots, anti-rolling, and anti-static treatments, thereby significantly increasing the probability of materials being output in the correct posture, reducing the occurrence of material jams and blockages, and ensuring a smooth feeding process.

品主圖480x480_柔性振動盤.jpg)

In multi-variety mixed-line production, rapid material switching is key to improving production efficiency. Danikor's flexible vibratory feeder feeding system has built-in multiple sets of material parameter programs, each corresponding to a set of independent parameter settings for a specific material, covering key parameters such as vibration frequency, feeding speed, and arrangement method. When changing production, staff only need to switch to the corresponding material program with one click, and the equipment can quickly adjust to the working state suitable for the new material, greatly shortening the changeover time, improving production efficiency, and reducing downtime caused by changeover.

For some special materials, Danikor's flexible vibratory feeder also features a quick tray change function. When it is necessary to handle materials with significantly different materials, shapes, or sizes, simply replace the pre-customized tray to achieve rapid changeover production. This function is not only easy and quick to operate but also ensures that the equipment can quickly return to an efficient feeding state after tray replacement, meeting the flexibility requirements of multi-variety production.

In addition, the tray of Danikor's flexible vibratory feeder can adopt a one-to-many design, which divides a larger tray into multiple independent feeding areas, each of which can be individually set and adjusted for different specifications of materials. This design is particularly suitable for compact workstations, making full use of limited space resources while meeting the feeding needs of multiple materials. In actual production, through collaboration with robotic arms, the robotic arm can pick up materials from each feeding area in a predetermined order and place them, thereby achieving a small-batch, multi-variety mixed-line production mode, greatly improving production flexibility and resource utilization.

品主圖480x480_柔性振動盤.jpg)